New and disruptive watch oscillator. It's made in the form of an openwork circular plate of monocrystalline silicon coated with a layer of silicon oxide. The Zenith Oscillator is the brainchild of Guy Sémon, who is well known for high tech TAG Heuer projects, including the belt-driven Monaco V4, and the MikroPendulumS.

The Zenith Oscillator was manufactured using DRIE technology (Deep Reactive Ion Etching) whereby each individual unit is structurally and functionally identical to the others. This consistency in performance, dimensions and properties of the oscillating element is essential to achieve high accuracy in the operation of the watch.

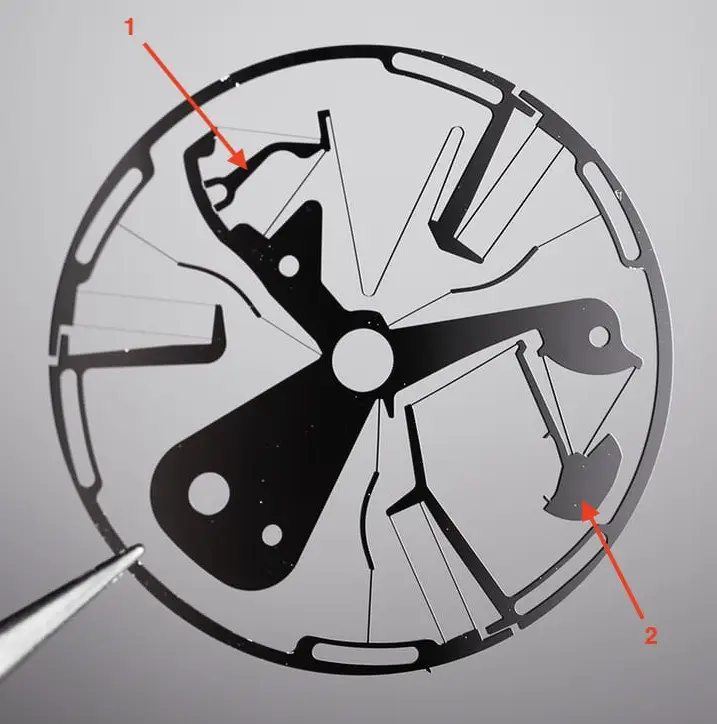

The oscillator was made in the form of a monolithic element with a diameter of about 30 mm and a thickness of 0.5 mm. Oscillating elements are thinner than a human hair (20 microns). The regulator (1) allows adjusting the rate by +/- 400 seconds per day. Moving it changes the tension of the flexible element of structure. The anchor escapement (2) has been integrated into the oscillator to form a monolithic unit with three non-circularly connected oscillating elements. Two eccentric screws allow precise adjustment of the position of the oscillator with regards to the escape wheel.

The Zenith oscillator combines high frequency (15Hz or 108,000 vibrations per hour) with low amplitude (+/- 6 degrees versus around 300 degrees for a conventionnal balance wheel) providing 60 hours power reserve.

Zenith announces a daily rate precise to 0.3 seconds per day.

Notifier: Tomasz Jakubas

Other records: Timeline of Watchmaking Innovations

INSTAGRAMIE

INSTAGRAMIE

greenlogic.eu

greenlogic.eu