In 2005, Ulysse Nardin—a brand renowned for its avant-garde horological innovations—unveiled the experimental timepiece Freak Diamond Heart 28,800 V/h. It was the first wristwatch to incorporate the Dual Direct escapement crafted from a pioneering material known as DIAMonSIL—a fusion of silicon and synthetic diamond.

DIAMonSIL – a breakthrough material for escapement components

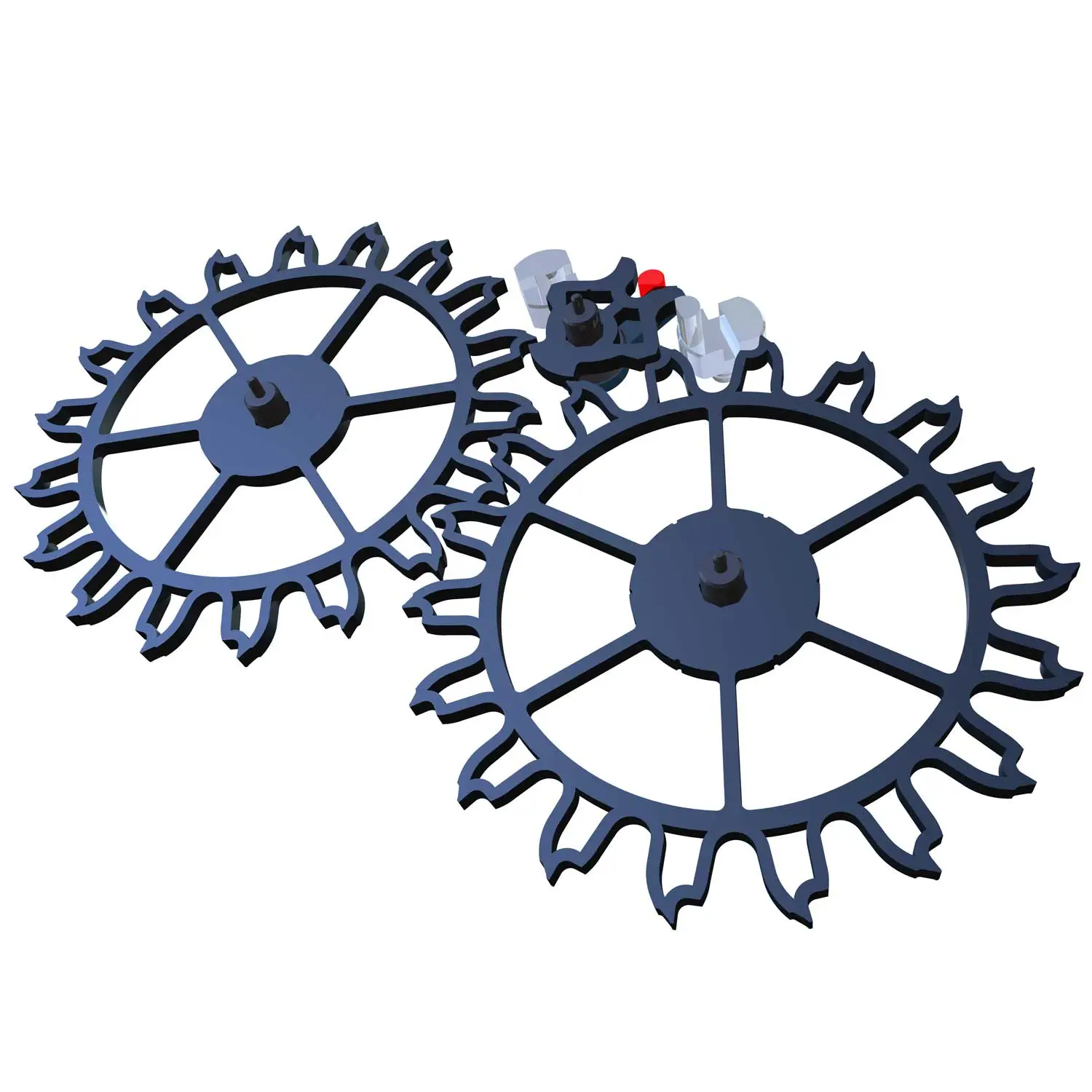

The technology enabling the creation of DIAMonSIL emerged from a collaboration between Ulysse Nardin and the German institute GFD (Gesellschaft für Diamantprodukte mbH)—a startup specializing in synthetic diamond production via chemical vapor deposition (CVD). This partnership gave rise to the unique Diamond Coated Silicon technology, resulting in the revolutionary DIAMonSIL material. In this high-performance composite, silicon components are coated with an ultra-thin layer of amorphous carbon exhibiting a diamond-like structure (DLC – Diamond-Like Carbon), effectively forming synthetic diamond surfaces. This coating dramatically increases wear resistance while preserving all the advantages of silicon: low mass, minimal friction (eliminating the need for lubrication), and immunity to magnetic fields.

The implementation of the Dual Direct escapement based on DIAMonSIL significantly reduced friction at critical contact points, enhancing the energy efficiency of the movement.

Operating at a frequency of 28,800 vibrations per hour (4 Hz), the Freak Diamond Heart marked a notable progression from earlier Freak iterations, which operated at lower frequencies.

The movement featured several groundbreaking characteristics:

- Absence of a traditional crown – Time-setting was performed by rotating a bezel integrated into the case.

- No conventional balance bridge – Both the balance wheel and escapement were integrated within a rotating module.

- Automatic winding system – Utilized Ulysse Nardin's proprietary winding mechanism.

The development and mastery of DIAMonSIL technology were the results of extensive research and were protected by numerous patents, including those covering diamond coating applications for silicon-based horological components. This innovation proved transformative not only for Ulysse Nardin but for the watchmaking industry as a whole, marking the dawn of modern materials in traditional mechanical watchmaking.

Ulysse Nardin became one of the first manufactures to extensively incorporate silicon and its hybrid derivatives into movement architecture. A direct outcome of these advancements was the introduction of the UN-118 calibre—a COSC-certified, self-winding movement with indications for hours, minutes, seconds, power reserve, and a date window positioned at 6 o’clock, with bi-directional date correction. Comprising 248 components, the calibre offered a 60-hour power reserve and operated at a frequency of 4 Hz (28,800 vph).

In 2006, Ulysse Nardin entered into a joint venture with Swiss firm Mimotec SA—a company specializing in micro-component fabrication via electroforming. Together, they established Sigatec, a manufacturer focused on producing high-precision silicon components using Deep Reactive Ion Etching (DRIE), and metallic components via LIGA (Lithographie, Galvanoformung, Abformung) technology. This facilitated industrial-scale production of ultra-precise, lightweight, corrosion-resistant, and non-magnetic parts, which have since become available to the broader horological community.

The influence of this technological milestone continues to resonate across modern watchmaking. The widespread adoption of silicon and related materials has become standard practice in the pursuit of enhanced precision, durability, and resistance to external factors.

Application: Tomasz Jakubas

Other records: Timeline of Watchmaking Innovations

INSTAGRAMIE

INSTAGRAMIE

greenlogic.eu

greenlogic.eu