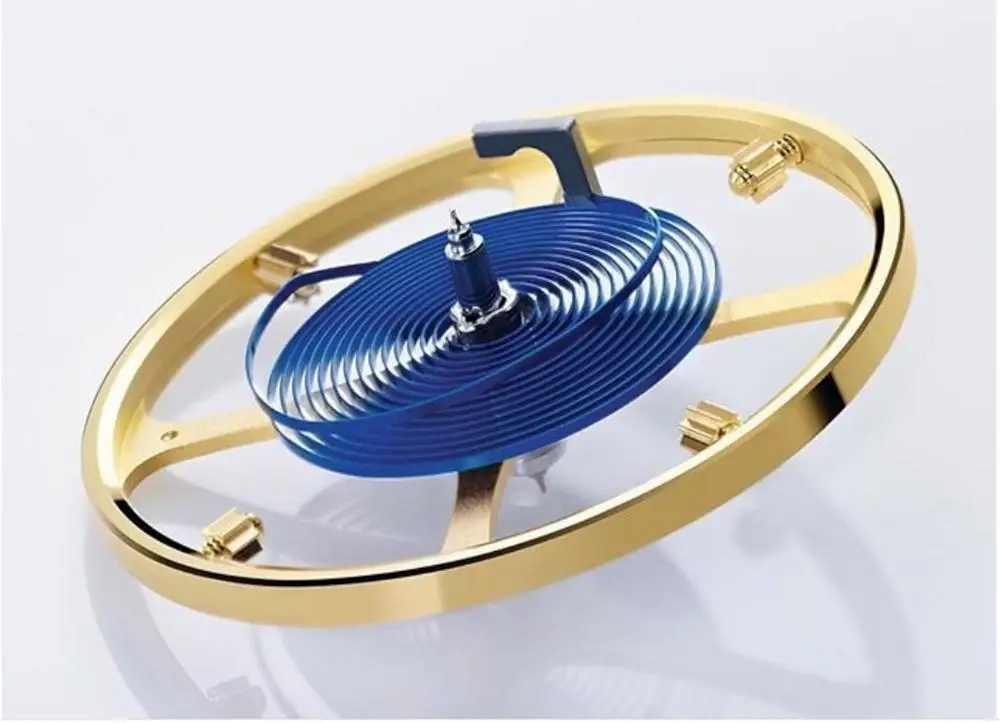

Parachrom – The alloy composed of 85% niobium and 15% zirconium, patented and manufactured by Rolex. The characteristic blue color and the name "Parachrom Bleu" come from an oxide layer 50-100nm [nanometres] thick. The alloy is a completely paramagnetic, virtually unaffected by temperature changes.

Due to its properties, it’s used to the manufacture of balance hairsprings.

Parachrom balance springs are manufactured in the Rolex laboratories. Before the material takes the shape of a spiral, niobium and zirconium are fused together at a temperature of around 2400° C, in a high vacuum environment. In The Plan-Les-Ouates, Rolex’s laboratory lies their own foundry, where the metals are passed through the furnace three times at 20cm an hour, under 5,000 volts.

As soon as the resulting rod of fused metal emerges, it reacts with the oxygen in the air and turns blue. During the forming process the metal rod is repeatedly processed in the press until that initial rod has been transformed into a strip nearly two kilometers long and 1/10th of a millimeter in diameter. During the final pass through the press, the dimensions of the strip are reduced to 150 microns wide and 45 microns thick. Received ribbon is then cut into 22cm lengths. Parachrom spirals are made with an accuracy of 0.1 microns (approximately one thousandth of the diameter of a human hair). Up to 10,000 balance springs are made from 30 cm of the initial piece of metal weighing approx. 0.5 kg.

Notifier: Tomasz Jakubas

Other records: Timeline of Watchmaking Innovations

INSTAGRAMIE

INSTAGRAMIE

greenlogic.eu

greenlogic.eu